Water jet cutting machine

EAAK water jet cutting machine application:

Can be used to cut almostly all the materials such as stainless steel,carbon steel,copper,brass,aluminum and other metals,glass steel,stone,glass,ceramics,plastics,composite and so on.High pressure abrasive waterjet cutting is currently the most applicable cutting method.

Can be used to cut almostly all the materials such as stainless steel,carbon steel,copper,brass,aluminum and other metals,glass steel,stone,glass,ceramics,plastics,composite and so on.High pressure abrasive waterjet cutting is currently the most applicable cutting method.

| Metal cutting: | |

| 1 | Decoration of stainless steel,aluminum.iron,brass and other metal cutting process. |

| 2 | Processing of machinery and equipment control cabinets such as food machinery,medical machinery,CNC machinery. |

| 3 | The metal parts cutting such as stainlesssteel flange,semi-finished,steel construction, non-ferrous metal and so on. |

| Glass cutting: | |

| 1 | Gas stove surfaces,range hood,disinfecting cabinet,TV,bathroom products. |

| 2 | Construction and decoration glass,automotive glass. |

| Ceramic and stone cutting: | |

| 1 | Ceramic cutting for decoration and construction. |

| 2 | Marble mosaic,granite mosaicmstone plate cutting. |

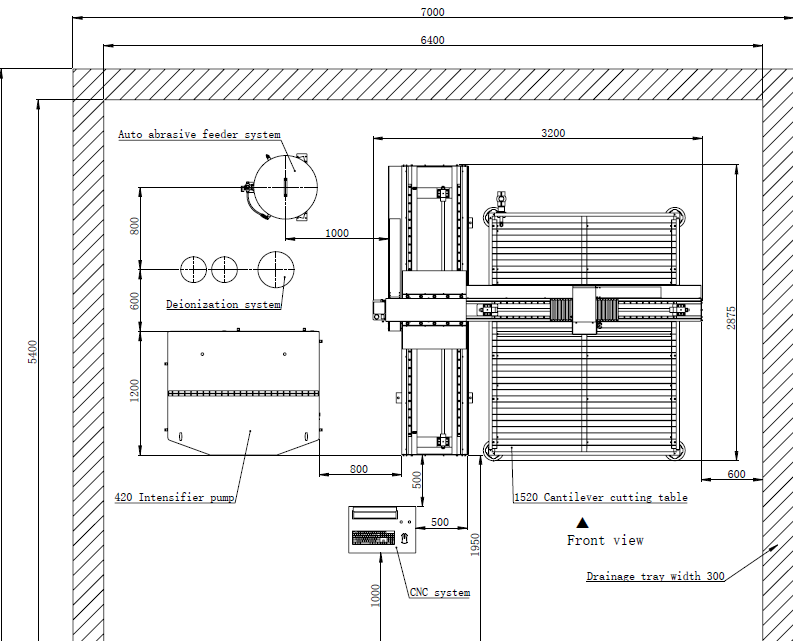

Specification of CNC waterjet cutting machine:(as follows)

Complete data and accurate design guarantee the CNC water jet machine with reliable performance:(as follows)

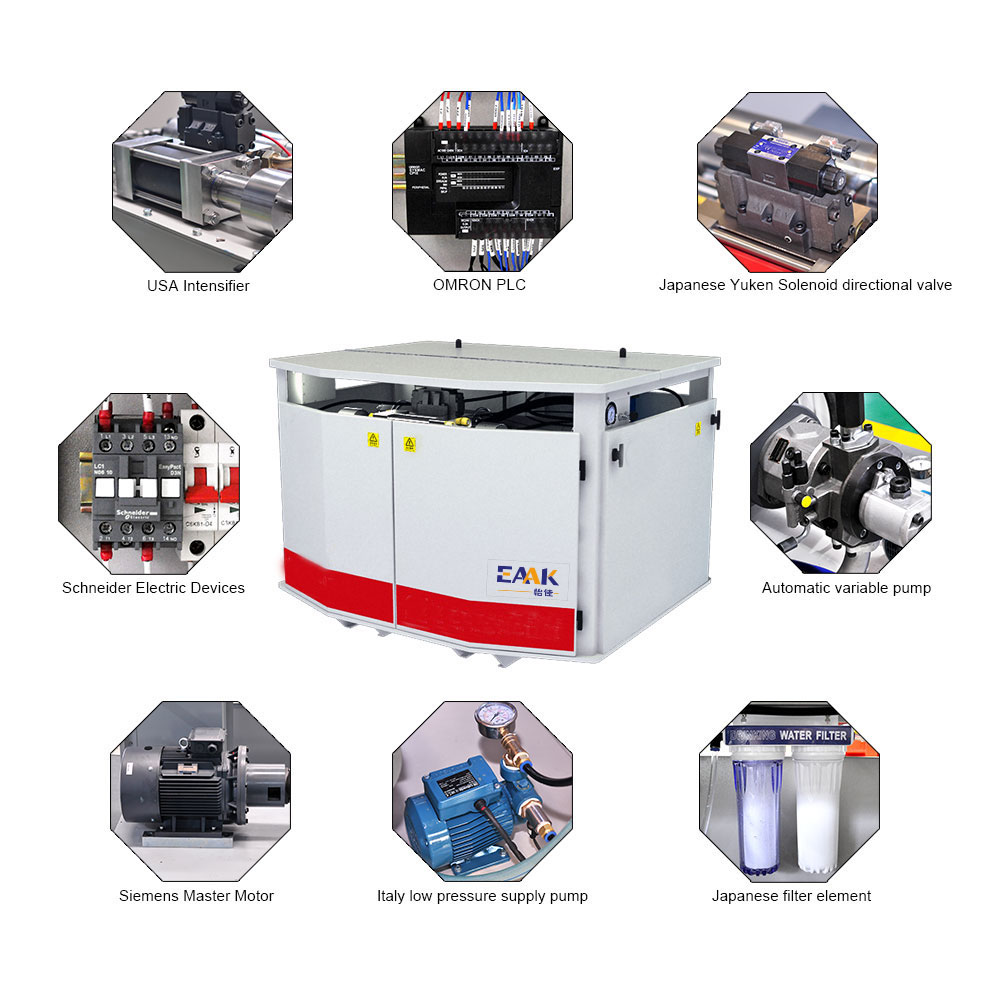

EAAK water jet cutting worktable:

Advantage of cantilevered platform on CNC water jet cutting machine (as follows):

High pressure water jet cutting pump:(as follows)| Model | EK1520 |

| X Y axis Working size | 1500mm*2000mm |

| Z working height | 150mm |

| Cutting Pressure | 420Mpa 37kw UHP pump |

| Control accuracy | 0.01mm |

| Cutting accuracy | 0.1-0.2mm |

| Repositioning Accuracy | 0.05mm |

| Max cutting thickness | 300mm(depends on materials) |

| Max. moving speed | 6000mm/min |

| Power supply | 380V 50Hz |

| Environmental temperature | -10-50°C |

| Max flow rate | 3.7L/min |

| Max oil discharge | 206L/min |

| Max delivery capacity of oil pump | 106L/min |

| Control system | Ncstudio (Shanghai) software IPC controller |

| CAD/CAM software | AutoCAD,ArtCAM |

| Drive motor | Japan Yaskawa servo drive motor |

EAAK water jet cutting worktable:

|

1,The overall structure of the cutting platform is reasonable in design,and the overall modular assembly is convenient for loading and unloading workpiece;

2,The water tank bearing platform and the frame structure are separated, and the water level adjustment function can be customized;

3,Customized protective gratings and splash-proof screens in the work area comply with EU regulations.

Gantry type: structural stability in line with international mainstream trends;

Cantilever type: three-sided open platform for easy loading and unloading.

|

|

| 1 | Open on three sides of the table, loading and unloading more convenient. |

| 2 | The machine bed and the load-bearing platform sub-structure, the load-bearing platform for long-term force change will not affect the machine precision, the number of Control movement institutions and support the workpiece table for the sub-structure, to put an end to the cutting process due to water flowing in sports degrees. |

| 3 |

Cutting platform X beam (gantry) using disposable aluminum extrusion Material, light weight, steel is strong, is not deformed.At present, water jet cutting machine Bed in the most advanced technology.

|

| 4 | Y to the whole protective cover, X to the use of advanced labyrinth protection to avoid cutting the pollution of the process of dust on the drive components Transfection; high-quality child care chain and a dedicated cable, durable, high reliability. |

| 5 |

To drive the servo motor and ball screw connected by a flexible coupling directly connected to reverse the rigid coupling phase with other.Has the advantages of Reversible absorb vibration transmission accuracy.

|

| 6 |

With the international brand of high quality ball screw, linear motion guide drive mechanism to ensure that the movement speed and precision of the cutting head.degree, 3m above itinerary is a turn Nut transmission. Long distance transmission more reliable super automatic travel limit and soft limit Bit dual protection function.

|

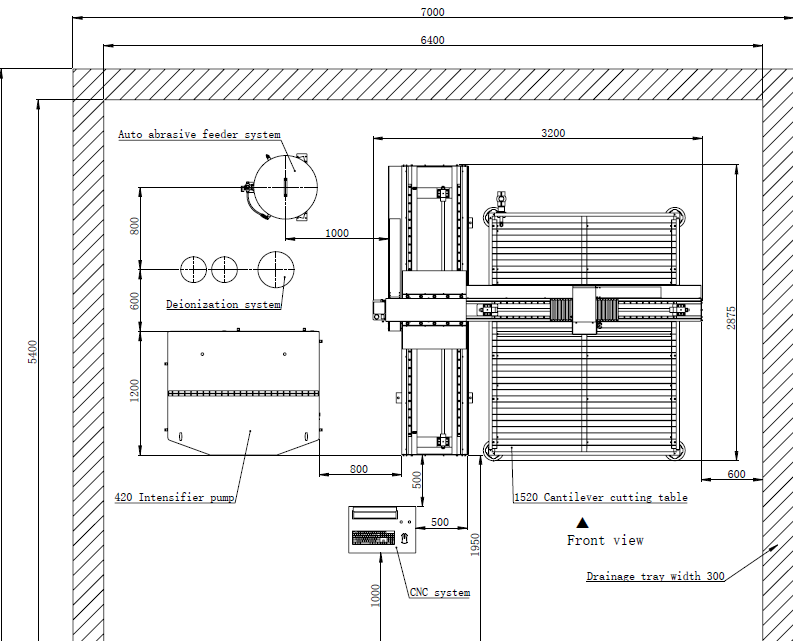

Adopting the current advanced design concept and structural design, equipped with imported high-quality supercharger and automatic variable oil pump, the cutting ability is strong, the performance is stable, and it can work continuously for a long time, which is suitable for large-scale batch production.

|

|

| Parameters of EAAK 420 Mpa high pressure waterjet cutting machine pump:(as follows) | |

| Maximum output pressure:420Mpa | Continuous working pressure: 370-390Mpa |

| Maximum oil pressure: 21Mpa | Maximum flow: 3.7LPM |

| Power supply: 380V/3P/50Hz | System power: 37KW |

| Maximum water nozzle diameter: 0.35mm | |

| Feature of EAAK high pressure water jet cutting pump:(as follows) | |

| 1 | Equipped with Siemens (Beide) three-phase asynchronous motor. |

| 2 | Equipped with brand automatic variable oil pump to improve energy efficiency. |

| 3 | Equipped with Japanese Omron PLC control. |

| 4 | Equipped with imported reversing valve, relief valve and cartridge hydraulic valve. |

| 5 | Equipped with Schneider AC contactor. |

| 6 | Equipped with imported high-pressure pipeline. |

| 7 | Equipped with cylinder piston running overclock protection. |

| 8 | Equipped with slow start function, low pressure mode, can automatically reduce pressure and noise at startup. |

| 9 | Equipped with low pressure water shortage automatic protection function (when the water inlet pressure is low, the pump will automatically suspends operation) |

| 10 | Equipped with the use of Italian imported blade type low-pressure water supply pump, small size, large water supply, pressure stability. |

| 11 | Equipped with motor overload overcurrent protection. |

| 12 | Equipped with low-pressure drilling, high-pressure cutting function, can achieve automatic conversion of high and low pressure. |

| 13 | Install the visual cover, easy to observe, beautiful and generous. |

|

1,The bottom roller design, easy to move when operating, observe the cutting situation.

2,The console is flat, large in area and easy to operate.

3,Equipped with a wireless operating handle for easy tool setting.

4,High quality professional industrial control computer.

5.Electrical and wiring meet European industrial standards.

6,Automatic tool compensation settings.

7,Based on the windows8 system, the software is easy to operate, one day will be.

8,Path simulation can be performed before cutting, with automatic programming.

9,Open compatibility system, more functional modules are optional.

|

Inteligent control system | |

|

|

||

|

|

||

|

|

||

Parameters of CNC waterjet cutter working on different materials such as glass,metal,stone(as follows)

| Materials | Thickness | Cutting speed (mm/min) | ||

| 380Mpa | 420Mpa | 600Mpa | ||

| Normal glass cutting | 6 mm | 1400-1500 | 2100-2250 | 2520-2700 |

| 8 mm | 690-800 | 1035-1200 | 1242-1440 | |

| 19mm | 400-500 | 600-750 | 950-1150 | |

| Granite panel cutting | 20mm | 260-300 | 390-450 | 468-540 |

| 30mm | 170-200 | 255-300 | 306-360 | |

| Porcelain tile cutting | 10mm | 900-1000 | 1350-1500 | 1620-1800 |

| Marble panel cutting | 10mm | 600-900 | 900-1350 | 1080-1620 |

| 20mm | 350-400 | 526-600 | 630-720 | |

| 30mm | 260-300 | 390-450 | 468-540 | |

| Laminating glass cutting | 21mm | 490-600 | 735-900 | 882-1080 |

| Sponge and foam cutting | 20mm | 6000-7000 | 9000-10500 | 10800-12600 |

| 50mm | 2600-3000 | 3900-4500 | 4680-5400 | |

| 80mm | 1600-2000 | 2400-3000 | 2880-3600 | |

| Steel plate cutting | 10mm | 170-220 | 255-330 | 306-396 |

| 20mm | 75-100 | 113-150 | 135-180 | |

| 30mm | 15-30 | 22-45 | 27-54 | |

| Stainless steel plate cutting | 1 mm | 1000-1200 | 1500-1800 | 1800-2160 |

| 3 mm | 500-600 | 750-900 | 900-1080 | |

| 6 mm | 240-300 | 360-450 | 432-540 | |

| 10mm | 150-180 | 225-270 | 270-324 | |

| 16mm | 85-100 | 128-150 | 153-180 | |

| 20mm | 70-80 | 105-120 | 126-144 | |

| 30mm | 30-40 | 45-60 | 54-72 | |

| Copper plate cutting | 3 mm | 1350-1500 | 2025-2250 | 2430-2700 |

| 5 mm | 700-850 | 1050-1275 | 1260-1530 | |

| 20mm | 160-200 | 240-300 | 288-360 | |

| 30mm | 100-120 | 150-180 | 180-216 | |

| Titanium alloy cutting | 13mm | 100-115 | 150-173 | 180-207 |

| Installation of waterjet cutting machine: | |

| We provide demonstration disk,tool kit,toolbox and some spare parts without charge for customer's self-installation.We also provides 7-10 days training for setting up, operating and maintenance. | |

| Training for EAAK waterjet machine customer: | |

| 1 | Our engineer goes to customer's factory and train onsite.The customer shall afford visa cost, round-trip air-tickets, food & hotel. |

| 2 | Customer come to our company and take free training for 10-15 days. |