5 axis water jet cutting machine

| 5 axis water jet cutting machine is suitable for cutting marble,granite mosic,ceramic tile and other thick materials and guarantee the cutting edge is with the right angle what customer needed.We have AC 5 axis cutting head and AB 5 axis cutting head for customer to choose. | |

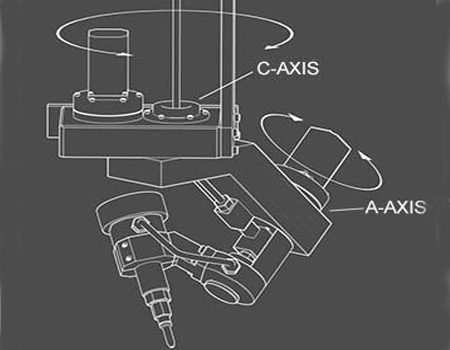

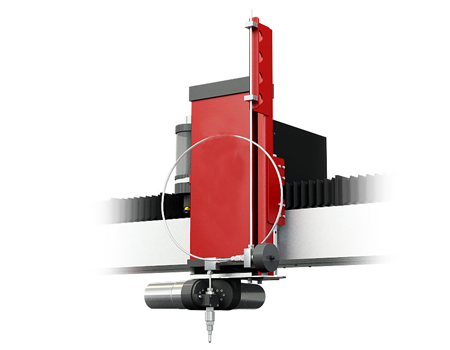

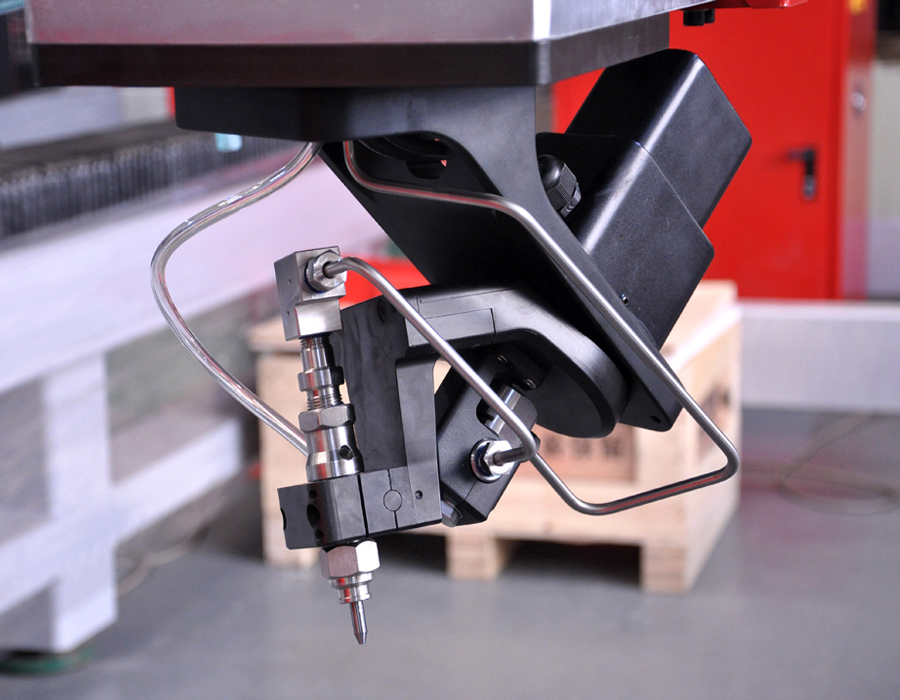

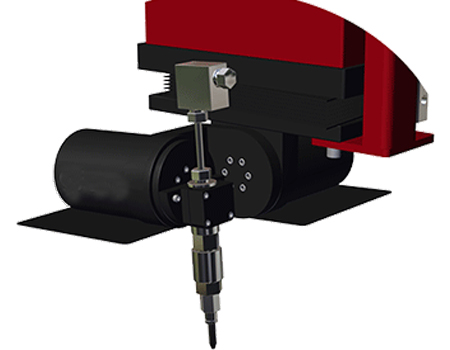

| AC axis waterjet cutting head | AB 5 axis waterjet cutter head |

|

|

| The EK 5X-AC five-axis cutting system adds an A-axis (rotation around the X-axis, ie yaw angle) based on the standard three-axis (X-axis Y-axis Z-axis). The C-axis (rotates around the Z-axis, ie rotates) Axis), can achieve large angle yaw, the maximum yaw angle can reach 75 °, Z-axis stroke is equivalent to the standard waterjet. At present, the five-axis system popular in the international market is AC five-axis. | The EK5X-AB five-axis water cutting system is a solution provided by Hyde for the high-quality ceramics, the stone-decoration industry, the reverse skew and the non-ferrous metal vertical precision cutting industry. By changing the inclination angle of the cutting head in the horizontal and vertical directions at the same time, the arbitrary angle control of the cutting head can be realized, and the maximum inclination angle is 8 degrees, and the angle can be finely adjusted according to different requirements to realize precise cutting of various materials. |

|

1,,Unique high-pressure pipeline built-in design, innovative breakthrough, no obstacles in the movement of the cutter head, the maximum yaw angle can reach 75°.

2,EAAK's original rotary joint design facilitates the replacement of accessories, reasonable structure and beautiful appearance.

3,The fixed rotary joint and the high-pressure pipe support structure ensure that the rotary joint is stably rotated by the shaft center to prolong the service life.

4,The operating software post processing is compatible with the European IGEMS CAM software, enabling simultaneous 2D and 3D cutting.

5,The imported high-precision servo motor and reducer replace the costly hollow core motor, reduce the volume, reduce the motor power and save energy.

6,The exterior is industrially designed and highly technical. The overall shape of the cutter head is made of aluminum alloy and stainless steel. It is light in weight and high in strength. It does not increase the load on the X-axis aluminum beam and has high cutting precision.

|

1. Using the AB axis structure, the CNC five-axis linkage is realized.

2. It adopts imported reducer, few parts, simple and beautiful structure, easy to understand, easy to learn and easy to maintain.

3. The use of Yaskawa servo motor effectively improves the accuracy of cutting and control.

4. Without the use of rotary joints, the number of wearing parts is greatly reduced, and the user's use cost is reduced.

5. The integrated dustproof sealing structure improves the service life of the equipment.

6. Original imported linear guide and screw lifting structure make the whole cutter head more stable and reliable.

|

|

|

| Parameters of CNC waterjet cutter working on different materials such as glass,metal,stone(as follows) | ||||

| Materials | Thickness | Cutting speed (mm/min) | ||

| 380Mpa | 420Mpa | 600Mpa | ||

| Normal glass cutting | 6 mm | 1400-1500 | 2100-2250 | 2520-2700 |

| 8 mm | 690-800 | 1035-1200 | 1242-1440 | |

| 19mm | 400-500 | 600-750 | 950-1150 | |

| Granite panel cutting | 20mm | 260-300 | 390-450 | 468-540 |

| 30mm | 170-200 | 255-300 | 306-360 | |

| Porcelain tile cutting | 10mm | 900-1000 | 1350-1500 | 1620-1800 |

| Marble panel cutting | 10mm | 600-900 | 900-1350 | 1080-1620 |

| 20mm | 350-400 | 526-600 | 630-720 | |

| 30mm | 260-300 | 390-450 | 468-540 | |

| Laminating glass cutting | 21mm | 490-600 | 735-900 | 882-1080 |

| Sponge and foam cutting | 20mm | 6000-7000 | 9000-10500 | 10800-12600 |

| 50mm | 2600-3000 | 3900-4500 | 4680-5400 | |

| 80mm | 1600-2000 | 2400-3000 | 2880-3600 | |

| Steel plate cutting | 10mm | 170-220 | 255-330 | 306-396 |

| 20mm | 75-100 | 113-150 | 135-180 | |

| 30mm | 15-30 | 22-45 | 27-54 | |

| Stainless steel plate cutting | 1 mm | 1000-1200 | 1500-1800 | 1800-2160 |

| 3 mm | 500-600 | 750-900 | 900-1080 | |

| 6 mm | 240-300 | 360-450 | 432-540 | |

| 10mm | 150-180 | 225-270 | 270-324 | |

| 16mm | 85-100 | 128-150 | 153-180 | |

| 20mm | 70-80 | 105-120 | 126-144 | |

| 30mm | 30-40 | 45-60 | 54-72 | |

| Copper plate cutting | 3 mm | 1350-1500 | 2025-2250 | 2430-2700 |

| 5 mm | 700-850 | 1050-1275 | 1260-1530 | |

| 20mm | 160-200 | 240-300 | 288-360 | |

| 30mm | 100-120 | 150-180 | 180-216 | |

| Titanium alloy cutting | 13mm | 100-115 | 150-173 | 180-207 |

- 上一篇:没有了

- 下一篇:没有了